How To Repair A Gerber Toilet Model # 400akrp10

The toilet is one of the nearly important fixtures in your home. Although toilets are sturdy and reliable components of the plumbing arrangement, it'south a rare homeowner or apartment-dweller who never has any problems with a toilet. Clogging is perhaps the well-nigh common toilet trouble, simply it is far from the only one. The tank, for example, can brand all sorts of strange noises, or h2o can run continuously. Fortunately, most toilet troubles tin can be fixed by a do-information technology-yourself plumber.

If you're a exercise-it-yourself kind of person, learning some quick fixes can keep you lot from calling the plumber. In this commodity, we're going to explain diverse issues related to repairing toilets.

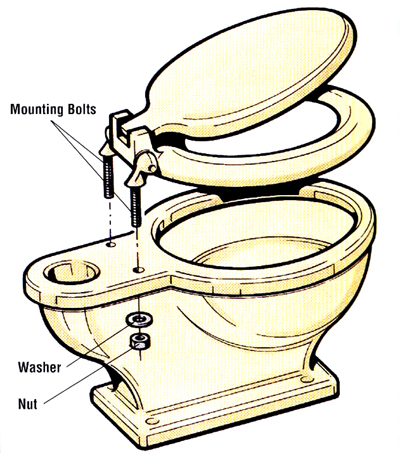

Replacing a Toilet Seat

The easiest toilet repair task is replacing the lid and seat. There are and then many styles of replacement seats available that you should have no trouble finding ane to match whatever bathroom color scheme or motif. Nearly modern toilets are manufactured in two standard sizes, and replacement seats are made to fit them.

Once y'all have the right size seat, remove the old i. Remove the 2 nuts on the hinge and lift your old toilet seat upwards and out. A common problem is that the basics securing the toilet seat may be rusted or corroded. The nuts on some toilet seats are recessed and practically inaccessible, making the job fifty-fifty more hard.

A new toilet seat can be installed by inserting the two bolts, slipping on the washers, and tightening the nuts. Be careful not to over-tighten the nuts or the seat might exist difficult to remove afterward.

What's the solution? If you tin can become to the fasteners relatively hands, apply some penetrating oil to aid loosen them. Requite the oil plenty of fourth dimension to soak in. Use a wrench, or, if you lot can't reach the nuts with a regular wrench, a deep socket wrench. Be sure y'all don't use too much force; if the wrench slips off a stubborn nut, information technology could strike and crack the tank of the bowl or anything else information technology happens to hitting.

| Sink, Tub and Drain Troubleshooting Guide | ||

| Problem | Possible Cause | Solution |

| Water in tank runs constantly | Float ball or rod is misaligned. | Bend float rod advisedly to move ball and so it volition not rub against side of tank. |

| Float ball contains water. | Empty or supervene upon float ball. | |

| Float brawl non ascension loftier enough. | Carefully curve bladder rod downwardly, but only slightly. | |

| Tank ball not sealing properly at bottom of tank. | Remove any corrosion from lip of valve seat. Replace tank brawl if worn. Accommodate elevator wire and guide. | |

| Ballcock valve does not close off water. | Replace washers in ballcock associates or, if necessary, replace entire assembly. | |

| Toilet does not flush or flushes inadequately | Drain is clogged. | Remove blockage in drain. |

| Not enough h2o in tank. | Enhance water in tank by bending float rod up slightly. | |

| Tank ball falls back earlier enough water leaves tank. | Move guide upwards so tank brawl can ascent college. | |

| Leak where tank joins toilet bowl. | Tighten nuts on spud pipe; supersede irish potato washers, if necessary. | |

| Ports effectually bowl rim chock-full. | Ream out residue from ports. | |

| Tank whines while filling | Ballcock valve not operating properly. | Replace washers or install new ballcock assembly |

| Waster supply is restricted. | Bank check shutoff to make certain it's completely open. Check for calibration or corrosion at entry into tank on valve. | |

| Wet around fixture | Condensation. | Install foam liner, tank comprehend, drip catcher or temperature valve. |

| Leak at flange wax seal. | Remove toilet and install new wax ring seal. | |

| Leak at bowl-tank connection. | Tighten tater pipe nuts; replace worn spud washers, if necessary. | |

| Leak at water inlet connection. | Tighten locknut and coupling nut; supercede washers and gasket, if necessary. | |

| Crack in bowl or tank. | Supplant bowl, tank, or entire fixture. | |

If all else fails, y'all'll take to cut off the bolts with a hacksaw. To protect the basin's cease, utilise tape to the bowl at the spots the hacksaw bract is probable to rub against. So insert the blade under the hinge, and saw through the bolts. Be extremely cautious in using the saw—a careless slip with a hacksaw can crack the fixture only equally hands every bit a blow with a wrench.

With the nuts removed or the bolts cut, you can remove the old seat without further difficulty. Make clean the area before installing the new seat. The new on can be installed by inserting the bolts and tightening the nuts. Be careful not to over-tighten the nuts, as you lot may want to supervene upon this seat anytime as well. If y'all live in a rented apartment and install a new seat that you paid for yourself, be certain to keep the old i. When you're fix to leave, you tin can replace the new on with the original and have the new seat with you.

If the toilet hat and seat are still in expert condition, but the minor rubber bumpers on the bottom are in bad shape, y'all can purchase replacement bumpers at the hardware store. Some bumpers screw in; others must be nailed or glued into identify. Whichever type you lot take, try to install the new ones in holes that are close enough to muffle the original holes.

Clearing a Clogged Toilet

You can generally articulate a clogged toilet with a plunger, otherwise known as the plumbers' friend. Brand sure that there's enough water in the toilet bowl to cover the rubber suction loving cup, then work the handle of the plunger upwardly and down. If there isn't plenty water in the bowl, do not flush the toilet; flushing a chock-full toilet will just cause the bowl to overflow. Instead, bring a pan or pot of h2o from some other source to supply the water you need to cover the plunger cup. At that place are 2 types of plungers, and the one with a bulb-type head is especially effective for toilets. Some types have a fold-out caput that's designed for toilet employ.

Normally, whatever is blocking the toilet bleed is not very far abroad. If the plunger's activeness doesn't dislodge the clog, y'all can try to hook the blockage and pull information technology free. A wire coat hanger can sometimes do the job, but it is really a substitute for the closet or toilet auger.

Before using the plunger, make certain there'due south plenty water in the toilet bowl to cover the suction cup. Pump the plunger to dislodge the clog.

The auger has a long sleeve or tube to guide the serpent and auger claw into the trap. A crank on the cease enables you to turn the hook in the drain or trap. Here'south how to utilise it.

Stride ane: Insert the auger into the toilet trap and plow the crank until it feels tight. This means that the snake has twisted its manner to and into the blockage.

Stride two: When you pull in the auger, you should be able to remove whatever is bottleneck the toilet. If you aren't successful, try the cupboard auger several more than times. In some cases, yous may have to resort to pushing a regular plumbers' ophidian through the blockage.

Pace iii: When all else fails, the toilet may have to be removed from the floor and turned upside down so you can get a blockage. This is non what anyone would call an piece of cake job, so y'all should give the simpler methods as good a effort as y'all can earlier you lot remove the toilet. But removing the toilet is not across the capabilities of the boilerplate do-it-yourselfer, and this process is explained in the forthcoming section.

The cupboard auger has a long sleeve to guide the snake and auger hook into the trap. A creepo enables you lot to turn the hook and dislodge the blockage.

Toilet Tank Problems

Compared with a clogged toilet, tank troubles can seem relatively insignificant. Yet strange noises or continuous water running can be more annoying. They tin can also exist costing yous coin in wasted water. Fortunately, you can eliminate most tank troubles quickly and easily.

Toilet tank troubles are both common and annoying, and they could be costing you coin in wasted h2o. Nearly bug, however, can be eliminated apace and easily. This is a cross section of a typical toilet tank and its components.

In one case you lot know how the toilet works, you can start to look for the source of toilet tank problems. Lift the lid off your toilet tank, and you should exist able to follow this procedure quite hands.

When you lot trip the handle on the tank to flush a toilet, a trip lever is raised inside the tank. This lever lifts wires, which, in plow, raise the tank ball or prophylactic flap at the bottom of the tank. When the flush valve opening is clear, the water in the tank rushes out past the raised tank ball and into the toilet basin below. This raises the level of water in the bowl higher up the level of water in the toilet trap.

While the h2o is rushing out of the tank, the bladder ball, which floats on tiptop of the water in the tank, drops down. This pulls down on the float arm, raising the valve plunger in the ballcock assembly and allowing fresh water to flow into the tank. Since h2o seeks its own level, the h2o from the tank pushes the bowl h2o out into the drain, causing a siphoning action that cleans everything out of the bowl. When all the water is gone from the toilet bowl and air is drawn into the trap, the siphoning stops. Meanwhile, the tank brawl falls back into place, closing the flush valve opening.

As the water level rises in the tank, the bladder ball rises until the float arm is loftier enough to lower the valve plunger in the ballcock assembly and shut off the incoming water. If the water fails to shut off there is an overflow tube that carries backlog h2o down into the bowl to prevent the tank from alluvion. If h2o flows continuously out of the tank to the bowl and downwardly the drain:

Footstep 1: Lift up on the bladder arm. If the water stops, you know the problem is that the float ball doesn't rise far enough to lower the valve plunger in the ballcock associates. One reason could be that the bladder ball is rubbing against the side of the tank. If this is the case, bend the bladder arm slightly to move the ball away from the tank side.

If your toilet runs continuously, cheque the guide and lift wire that raises and lowers the tank ball to be certain they are aligned properly.

Pace ii: If the ball doesn't touch the tank, continue to hold the float arm and remove the ball from the stop of the arm by turning it counterclockwise. And then shake the ball to see if there's water inside it, every bit the weight of the water inside could exist preventing the ball from rising normally. If in that location is water in the ball, milk shake information technology out and put the ball back on the float arm. If the ball is damaged or corroded, supplant it with a new one. If there is no water in the ball, put the ball dorsum on and gently bend the float rod down to lower the level the float brawl must attain to shut off the flow of fresh water into the tank.

Step 3: If the above steps don't solve the problem, bank check the tank ball at the flush valve seat. Chemical residue from the h2o tin can forestall this ball from seating properly, or the ball itself may have decayed. Water will seep through the flush valve opening into the toilet bowl below. Turn off the water at the toilet shutoff valve and flush the toilet to empty the tank. Yous can at present examine the tank ball for signs of wear and examine the tank ball for signs of wear and install a new ball if necessary. If the trouble is chemical balance on the lip of the affluent valve opening, have some wet-dry out emery cloth, steel wool, or even a knife and clean away the debris.

Footstep 4: If the backlog water still flows through the toilet, the guide or the elevator wire that raises and lowers the tank ball may exist out of the line or bent. Make sure the guide is in place then that the wire is direct higher up the flush valve opening. Rotate the guide until the tank ball falls direct downward into the opening. If a lift wire is bent, endeavor to bend information technology back to the correct position, or install a new one. Make certain the trip lever rod is not rubbing confronting anything and the lift wire is non installed in the wrong pigsty of the rod; either situation could cause the tank brawl to fall at an angle and non block the opening as it should.

If neither the float brawl not the tank ball is at error, so the problem must be in the ballcock assembly.

Fixing a Toilet Ballcock Assembly

The ballcock assembly looks more complicated than it really is. When you go to a hardware or plumbing-supply shop to buy a new ballcock associates, you'll find that both plastic and metal units are available. Plastic costs less and will not corrode. But plastic assemblies are not as sturdy as metal ones. In add-on, plastic units ordinarily cannot be repaired because many of them are sealed. Nevertheless, you can purchase a blazon of unit of measurement different from the one you're replacing as long as the new assembly has a threaded shank the same size as the sometime 1. If possible, bring the old assembly with you when you to buy the replacement. Here's how to fix an older-style ballcock assembly:

Footstep 1: Make certain the h2o shutoff valve for the toilet is in the OFF position.

On many older ballcock assemblies, a pair of thumbscrews holds the valve plunger. You will accept to unscrew them to remove the valve.

Pace two: Remove the valve plunger, and you'll run into on or two washers or O-rings. If any of these parts is faulty, water will flow out by the plunger continuously, and the toilet volition run constantly. Examine all of the washers and supervene upon any defective ones.

Step 3: If the ballcock assembly is sealed, supervene upon it as a unit. Close off the toilet water supply at the shutoff valve and flush the tank. Unscrew the bladder arm from the former ballcock unit and remove the refill tube from the overflow tube.

Stride 4: Look nether the tank for a coupling or slip nut where the water inlet pipe enters the base of the tank. Loosen the coupling nut to free the water inlet pipe. So use an adjustable wrench to grip the retaining nut or locknut immediately in a higher place the sip nut nether the tank. Use another wrench to grip the base of the ballcock assembly shaft inside the tank.

Step 5: Unscrew the locknut under the tank to remove the ballcock associates. If the nut is stubborn, utilize penetrating oil to loosen it.

Stride six: Life the one-time assembly out of the tank, saving the washers from all connections, both inside and outside the tank. New ones will probably be included with the replacement unit, but keep the old parts until you've installed the new ballcock assembly in case new parts are damaged during installation.

When installing a new ballcock assembly, make sure the gasket and the washer are properly seated and firmly secured by the retaining unit.

Step 7: Insert the new ballcock assembly into the hole in the tank. With the within washer in place, tighten the locknut on the outside sufficiently to make the inside washer fit watertight against the hole, but don't over-tighten information technology.

Footstep 8: Replace the coupling nut and h2o inlet pipage, reinstall the float arm, and set the refill tube into the overflow tube.

Step 9: Turn the water back on at the toilet shutoff valve and check for leaks at all points. Of course, some other thing to check is that the float brawl does not rub against the back of the tank.

Newer types of ballcock assemblies eliminate the float arm and the float ball. Ane kind features a plastic cup that floats up to cut off the water as the tank fills. You tin set the water level in the tank by adjusting the position of the plastic cup on a pull rod. 1 advantage to this type of ballcock assembly is that it lets the water run total-force until the tank is filled. It then shuts the water off immediately, eliminating the groaning noises some toilets brand equally a float arm gradually closes the valve.

Ane blazon of diaphragm-powered valve rests shut to the lesser of the tank (left); it eliminates the float ball and float arm. Some other type (right) uses a flapper cover, lifted by a chain.

Another type of ballcock also eliminates the float ball and float arm. This is a small unit that rests almost on the bottom of the tank; it'due south diaphragm-powered valve senses the level of the water from down there. Moreover, since it requires no tools, this assembly is an easy unit to install. To install these newer ballcock assemblies:

Step 1: Plow off the tank's water supply shutoff valve. Then flush the toilet to bleed the tank. Sponge up whatsoever h2o remaining in the tank before proceeding.

Footstep 2: Remove the old ballcock assembly, following the procedure outlined above. Skid the parts over the water inlet pipage nether the tank in this lodge: coupling nut, friction washer, cone washer, and retaining or mounting nut.

Step iii: Install the new unit of measurement inside the tank, fitting the threaded shank downwardly through the pigsty over the water supply pipe and making sure the gasket fits into the hole. Start tightening the retaining or the mounting nut under the tank onto the threaded shank: manus-tighten it only. Push the washers into place and hand-tighten the coupling nut under tank; be conscientious not to over-tighten it.

Step iv: Within the tank, attach 1 end of the refill tube to the tank's overflow pipe and identify the other cease on the stem of the replacement unit of measurement.

Step 5: Open the water supply valve to fill the tank. The water level in the tank can be adjusted by a knob on the new valve unit.

Solving Common Toilet Issues

What tin you do if too little water comes from the tank to flush the toilet bowl clean?

Footstep 1: Check the water level in the tank. It's probably likewise low. If the water level doesn't reach within 1 ½ inches of the tiptop of the overflow tube, bend the float arm up slightly to let more water enter the tank.

Step ii: If the water level is correct but there's still not enough water coming from the tank to clean the bowl properly, the trouble may be the tank ball on the flush valve seat the bottom of the tank. The brawl is probably dropping too shortly considering the guide is set up likewise low. Raise the guide, but make certain it stays in line with the lift wire. If the guide and the wire are out of alignment, the tank ball will not drop straight into the valve seat opening, and the toilet volition run continuously.

Step iii: Look for other cause of inadequate flushing. The small ports around the underside of the toilet bowl's rim tin go clogged with residue from chemicals in the h2o and prevent a sufficient amount of tank h2o from running out into the bowl. A small mirror tin can help you lot examine the holes, and a piece of wire coat hanger or an offset Phillips screwdriver—if one is bachelor—tin ream out any clogged debris.

Here'south some other common problem amidst toilets. Toilet tanks can sweat and drip onto your floors simply every bit the pipes can. In that location are jackets designed specifically to fit over the tank and absorb the moisture. There are also drip pans that fit nether the tank to take hold of the dripping condensation so that it doesn't damage your bathroom floor. A device called a temperator valve is some other way to combat tank sweating. The valve provides a regulated mixture of hot and cold h2o, which lessens the difference betwixt the temperature inside the tank and the temperature of the surrounding air. It is this difference in temperature that causes condensation, or sweating. Consider installing a temperator valve if the water in the tank is usually below 50 degrees Fahrenheit.

The temperator valve, which requires both hot-h2o and cold-water supply connections, tin reduce toilet tank sweating.

A temperator valve requires you to hook up a hot-water line to the valve, which may be quite inconvenient if there is no such line relatively close to the toilet. Moreover, the temperator valve does not forestall the water inside the tank from cooling between flushings: thus, condensation tin however occur fifty-fifty on a temperator-equipped toilet. A leak may be due to loose connections or lacking washers on the potato piping or where the h2o inlet pipe and ballcock associates are attached to the tank. Supercede whatever worn gaskets or washers and tighten all of the nuts, then test with bluing in the h2o.

It is likewise possible that water is seeping out from under the toilet bowl. The wax ring seal that joins the bowl to the drain outlet may be defective. If this is the instance, the bowl must be removed, and a new gasket installed. If the leak is due to a crack in the tank or bowl, the whole toilet must be replaced.

Replacing a Toilet

Removing and replacing a toilet is non a job to exist undertaken without good reason, but information technology is certainly non beyond your capabilities. When you tin't unclog the toilet by less desperate means, removing it is the answer. Maybe you lot want a more mod toilet, possibly the bowl or the tank is cracked, or mayhap the fixture leaks around its base. All of these situations call for removing and reinstalling the old toilet or installing a new fixture.

Although there'due south nothing difficult nearly removing and replacing a toilet, local plumbing lawmaking may prohibit anyone just a licensed plumber from doing the job. Check the code for your customs to make certain it is okay for you lot to undertake the job. To supplant a toilet:

Stride 1: Mensurate the rough-in distance—the altitude from the wall behind the basin to the eye of the toilet floor drain. Measure from the wall to the center of either of the two concur-down bolts, 1 on each side of the toilet, that agree the fixture to the floor. If there are two bolts on each side, mensurate to the heart of the rear bolt.

Step 2: Select the replacement toilet unit using the crude-in distance so that information technology will fit properly in your bathroom. Yous can replace your old toilet with a more modern fixture, but you must make sure that the new unit will fit into the space between the drainpipe and the wall. You lot can install a smaller unit, merely you cannot put a larger toilet into a infinite that was occupied by a smaller fixture.

Step 3: Shut off the water supply to the toilet tank, then remove all the h2o from both the tank and the bowl. Trip the flush handle to eliminate most of the h2o from the tank. So soak up whatever h2o is left with a sponge. Bail out the water in the basin with a small container, and so use a sponge to dry out the bowl completely.

Step four: If the tank is connected to the wall, remove the hanger bolts within the tank that secure the tank to the wall. Then remove the pair of bolts at the lesser of the tank that connect the tank to the bowl. Remove the tank and set it out of the way.

Footstep 5: Remove the caps over the agree-downwardly bolts at the base of the bowl if there any. Nigh of these caps are made of ceramic to match the basin. Some types are held on by plumbers' bring together compound and tin can be pried off with a putty knife; others are threaded and can be unscrewed. Later on removing the caps, brush abroad the dried compound before proceeding.

Step six: Remove the hold-downward nuts or bolts. These may be extremely stubborn, but some penetrating oil should make removal much easier. Salvage the washers and bolts if yous volition be reinstalling the bowl. Once the concord-down nuts or bolts are out, at that place'southward zilch else holding the bowl to the flooring. Caution: To prevent sewer gas from backing upwards the drain, you should plug the opening while you lot work. Tie a cord around an one-time towel so it won't fall through the opening, and jam this plug into the bleed.

Step 7: Remove the basin. Considering the bowl and the tank tin crack from only ane abrupt blow to the porcelain, spread out an quondam piece of carpeting on which you can lay the fixtures. You should besides have a bucket and sponge handy to soak upward the water you couldn't bail out before. With your work surface prepared, rock the bowl gently dorsum and forth to loosen it, and then lift it directly up. Information technology weights about 60 or 70 pounds. Set the bowl on the slice of carpet.

Step viii: Audit the uncovered drain. If necessary, clear the drain. In one case the pipage is clear, you can proceed with the replacement of the toilet.

Step 9: Putting in a new toilet and reinstalling the old i are washed in the same way. With a putty knife, scrape away all the one-time putty or other sealing material from both the bottom of the bowl and the floor flange.

Typical installing of a ii-piece floor-mounted toilet.

The rough-in distance can be measured with the toilet in place by measuring from the wall to the center of the hold-downwards commodities, or to the eye of the rear commodities if the fixture is held by two pairs of bolts.

Inspect the floor where the toilet was. If the floor has rotted, information technology will have to be rebuilt earlier the toilet can exist installed. Depending on how bad the damage is, the rebuilding may involve the floor, the subfloor, and fifty-fifty the joists. In this case, have a carpenter rebuilt the damaged area before you lot install the toilet. As well inspect the flange and the bolts that come upwardly from the flange. If the flange is damaged or the bolts are stripped, supersede the faulty role of parts before you go whatsoever further.

Pace 10: Install a new sealer ring on the water outlet opening on the lesser of the new bowl. With the fixture upside down, set the sealer ring into identify on the bottom of the bowl. If the floor flange is recessed, you lot'll need a gasket with a plastic sleeve in the ring. This sleeve should face up toward you as you lot position it, since it will go into the soil pipe.

Pace eleven: Apply a uniform layer of the toilet-bowl setting chemical compound well-nigh 2 1/8 inch thick around the border of the bowl at the base. This chemical compound is available at hardware stores and plumbing-supply stores.

Step 12: Remove the plug from the drain or soil piping. Turn the bowl correct side upwards and place it downwardly over the flange, guiding the bolts into identify. Press down firmly, and give the basin a slight twist to brand certain the wax ring seats properly against the flange. Place a level beyond the bowl to make sure that it is level. Motion the bowl as needed to level it, simply don't disturb or intermission the seal of the wax band or the toilet will leak.

Step thirteen: Hand-tighten the nuts to concur the bowl to the floor. Do not over-tighten the nuts, or else the fixture may crack. Glaze the concord-down nuts and bolts with toilet bowl setting compound and reinstall the caps.

Pace fourteen: If the tank and bowl are split fixtures, you lot should now adhere the tank. Rebolt a wall-mounted tank, or reinstall the bolts and washers that connect a basin-supported tank. Replace any damaged parts. If the tank and bowl are connected with potato pipe, apply piping joint chemical compound to the threads of the spud slip basics and tighten them in place.

Step 15: Reconnect the h2o supply inlet pipe to the tan, make sure the ballcock assembly is properly attached, and turn the water dorsum on.

Lots More than Data

Source: https://home.howstuffworks.com/home-improvement/plumbing/how-to-repair-a-toilet.htm

Posted by: smithmallons01.blogspot.com

0 Response to "How To Repair A Gerber Toilet Model # 400akrp10"

Post a Comment